- Sorry, this product cannot be purchased.

Products

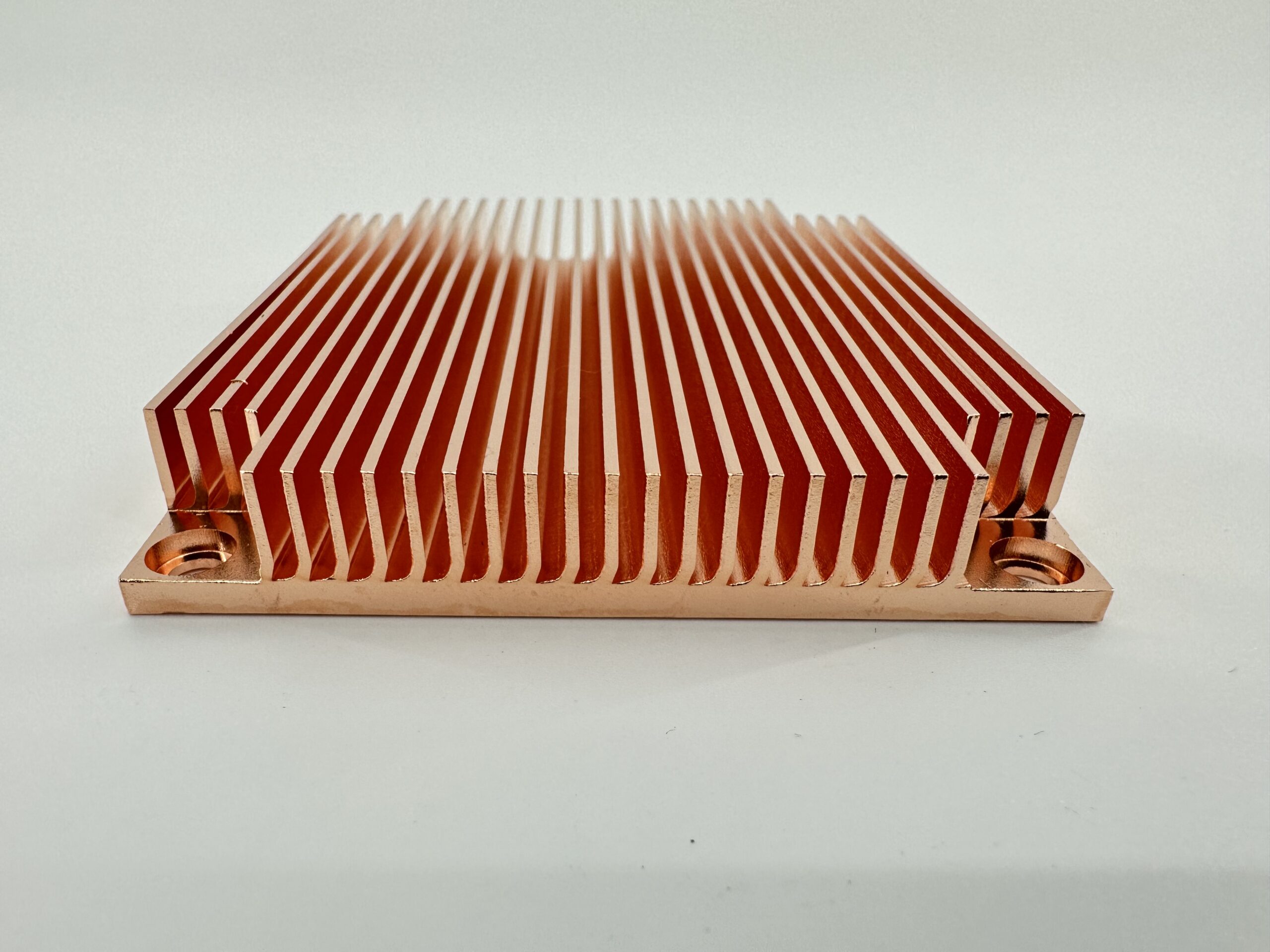

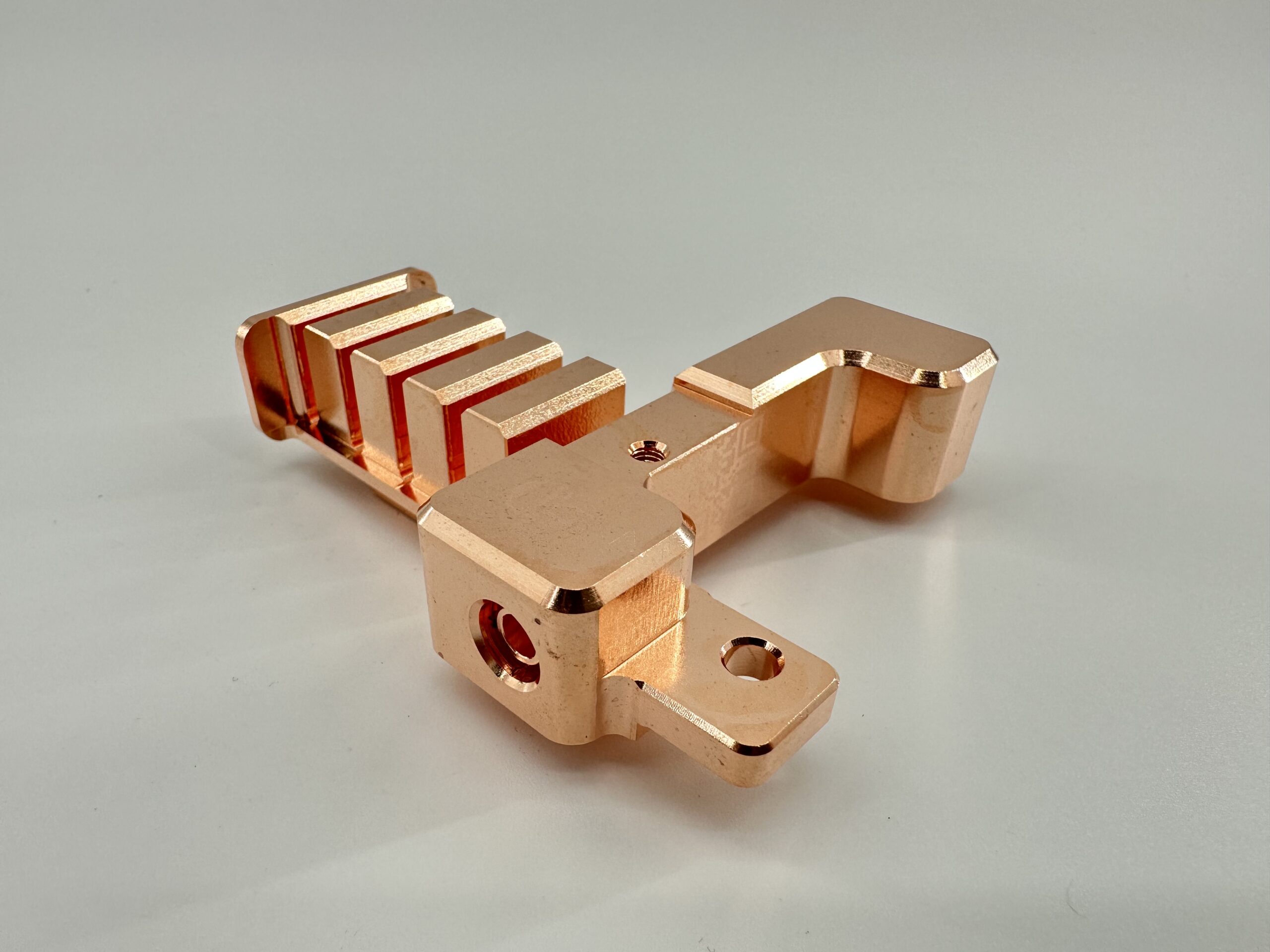

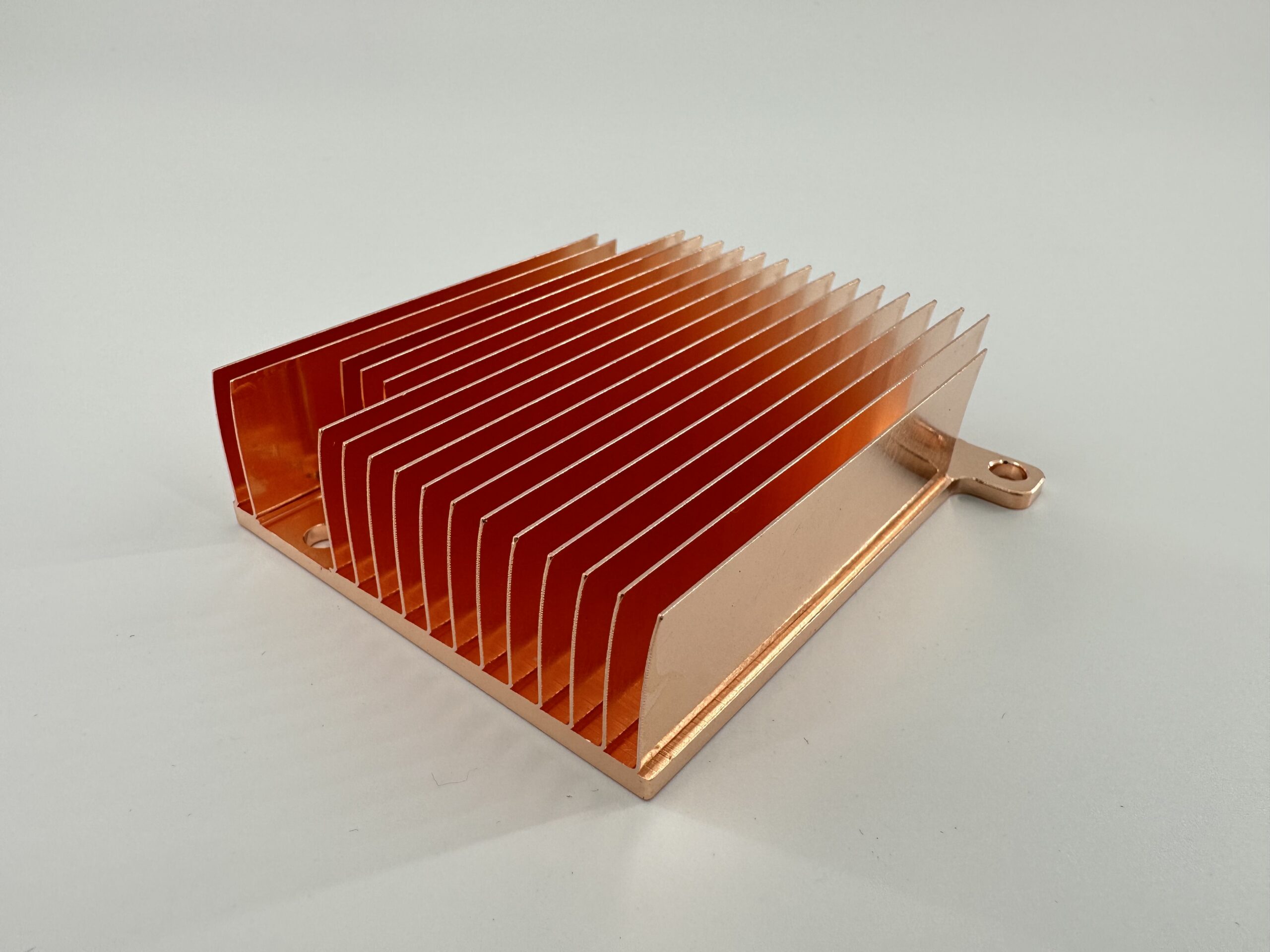

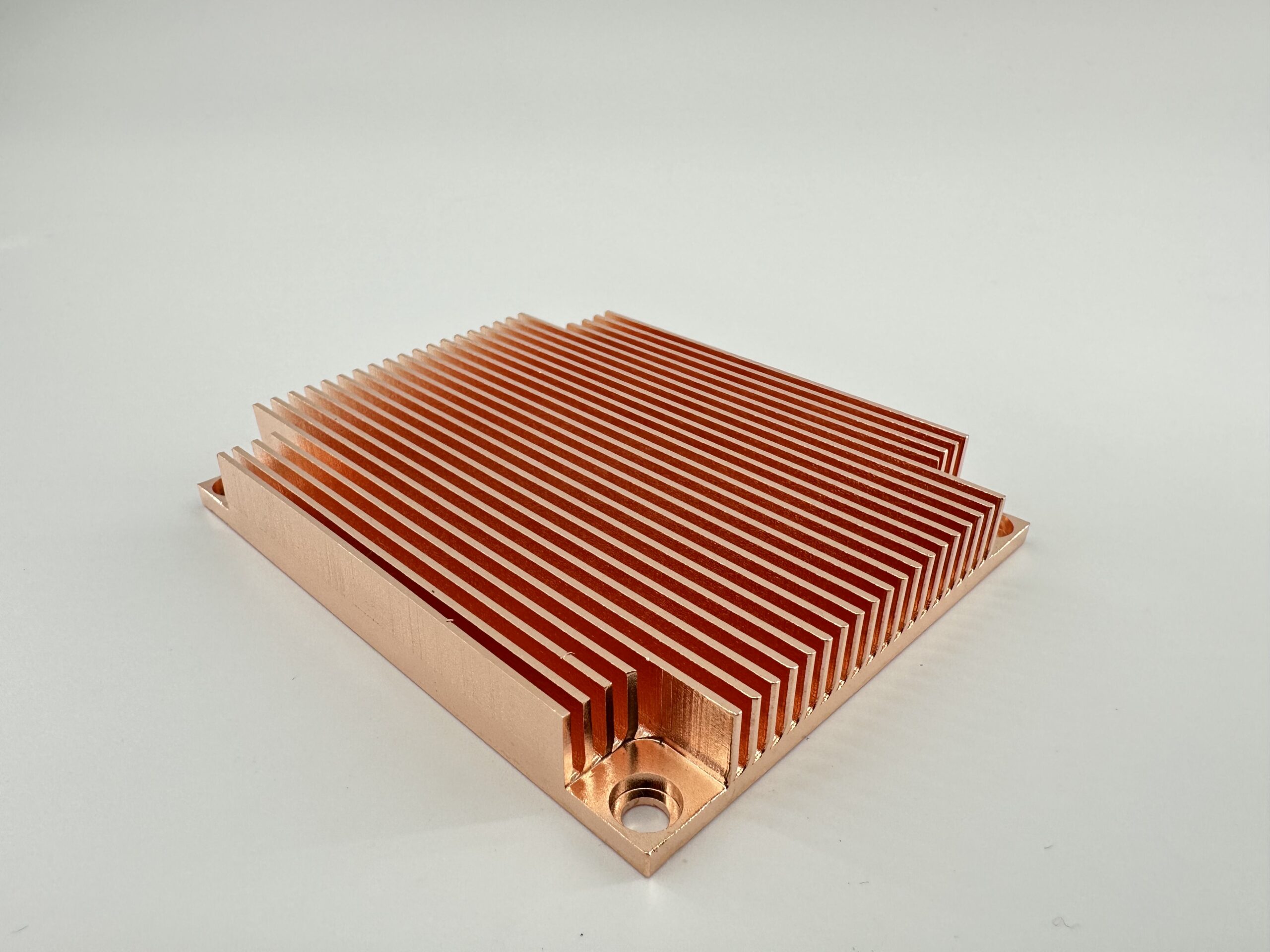

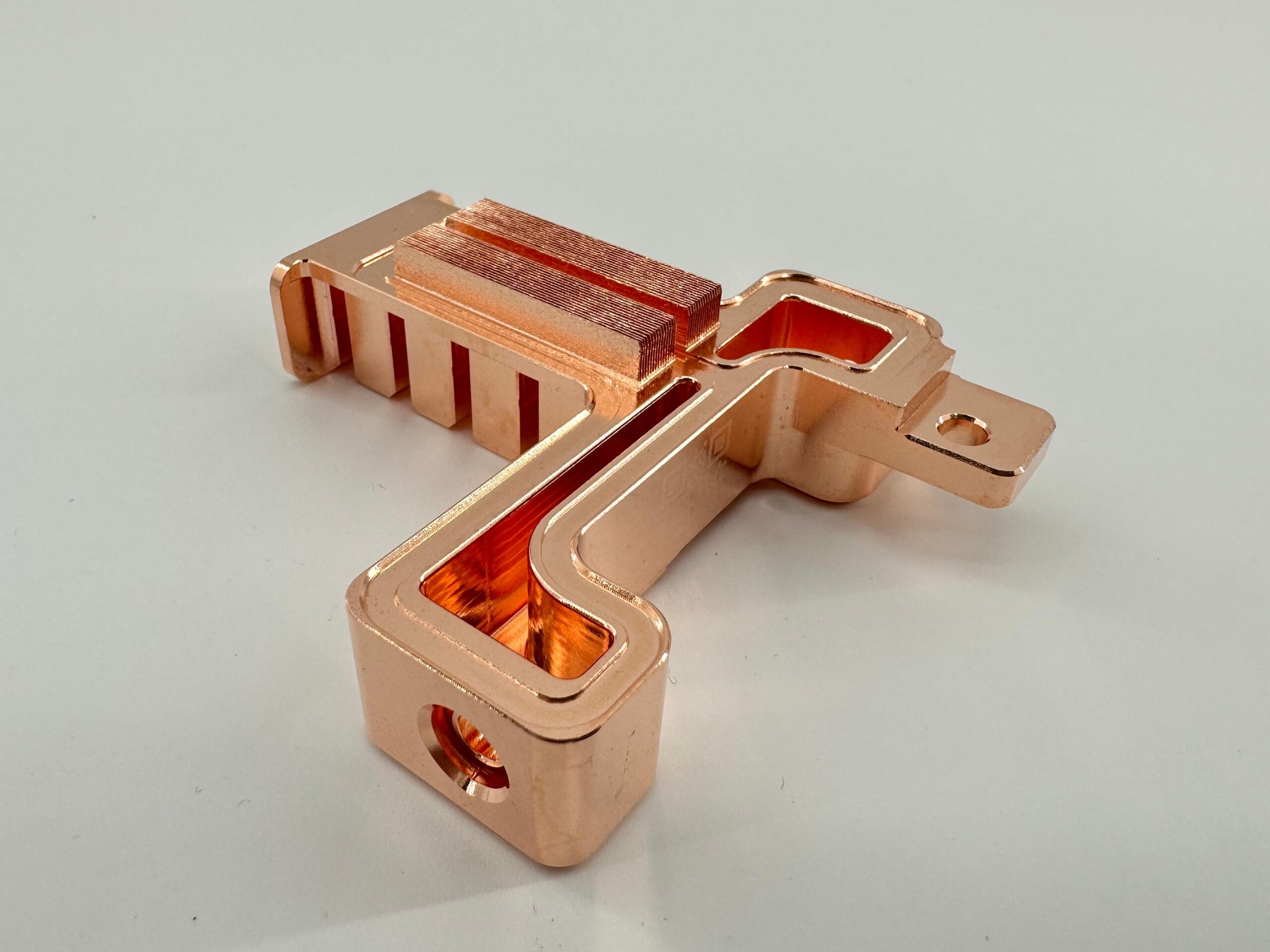

Skived Heat Sink

What is a Skived Heatsink?

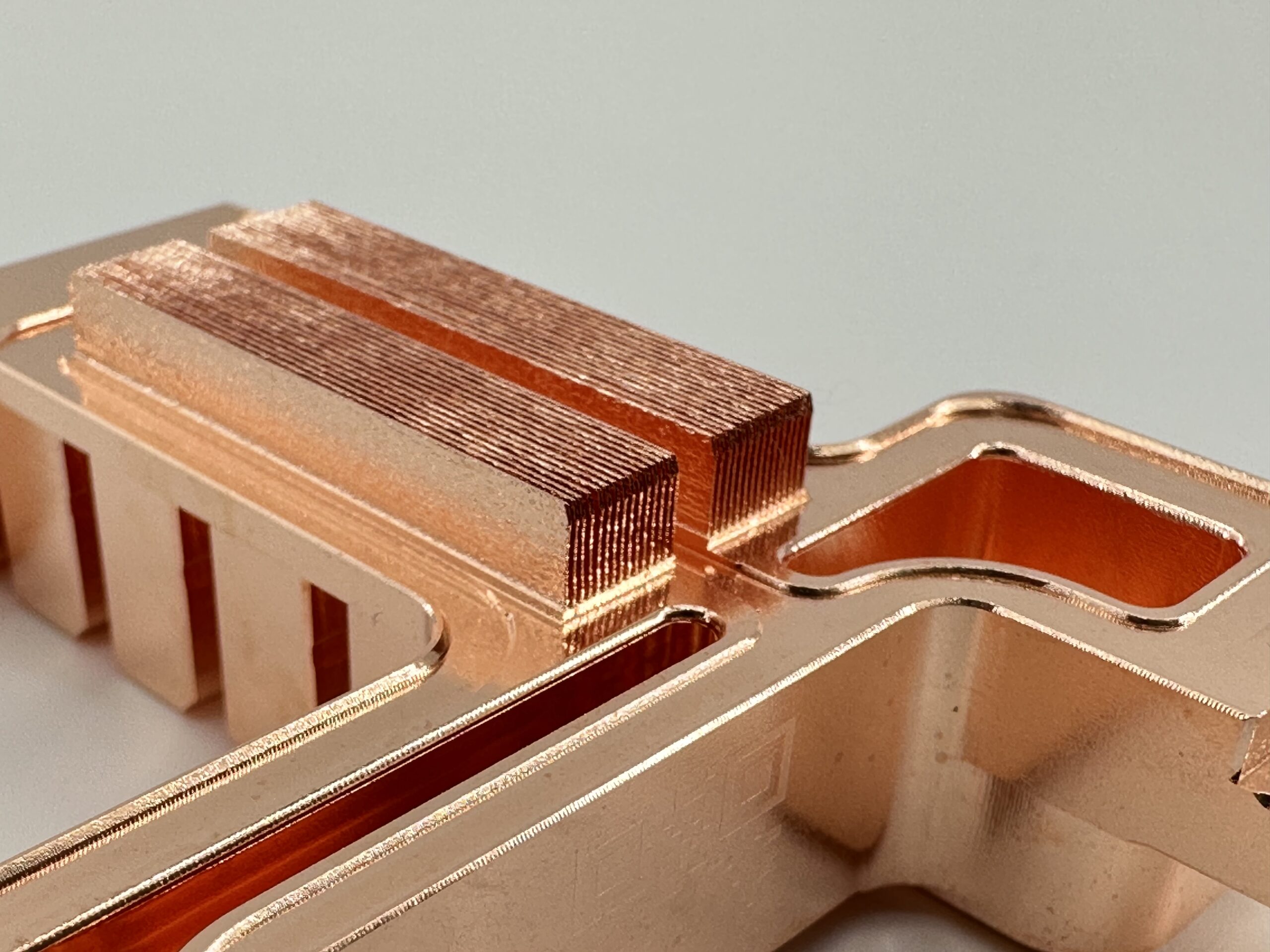

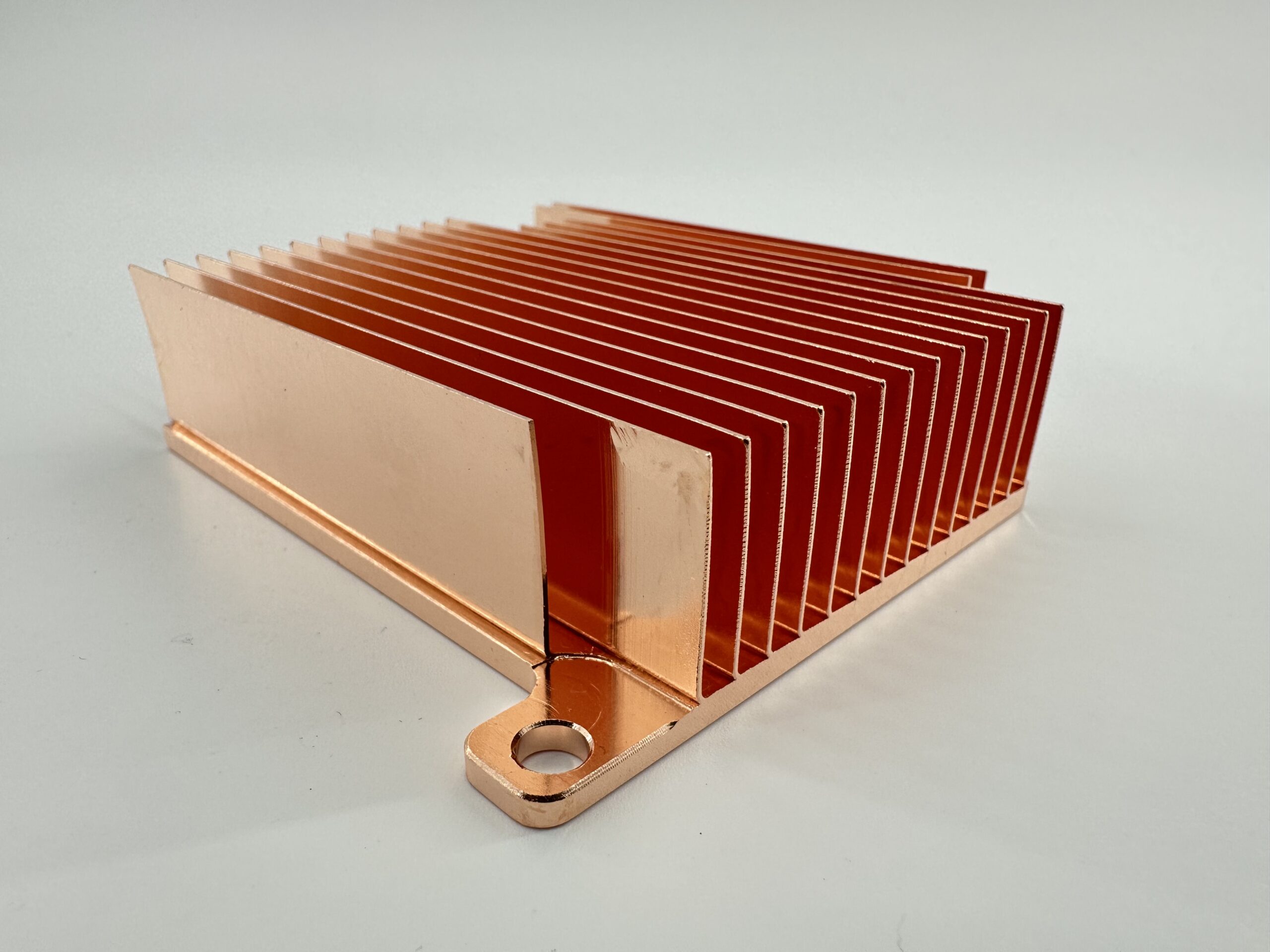

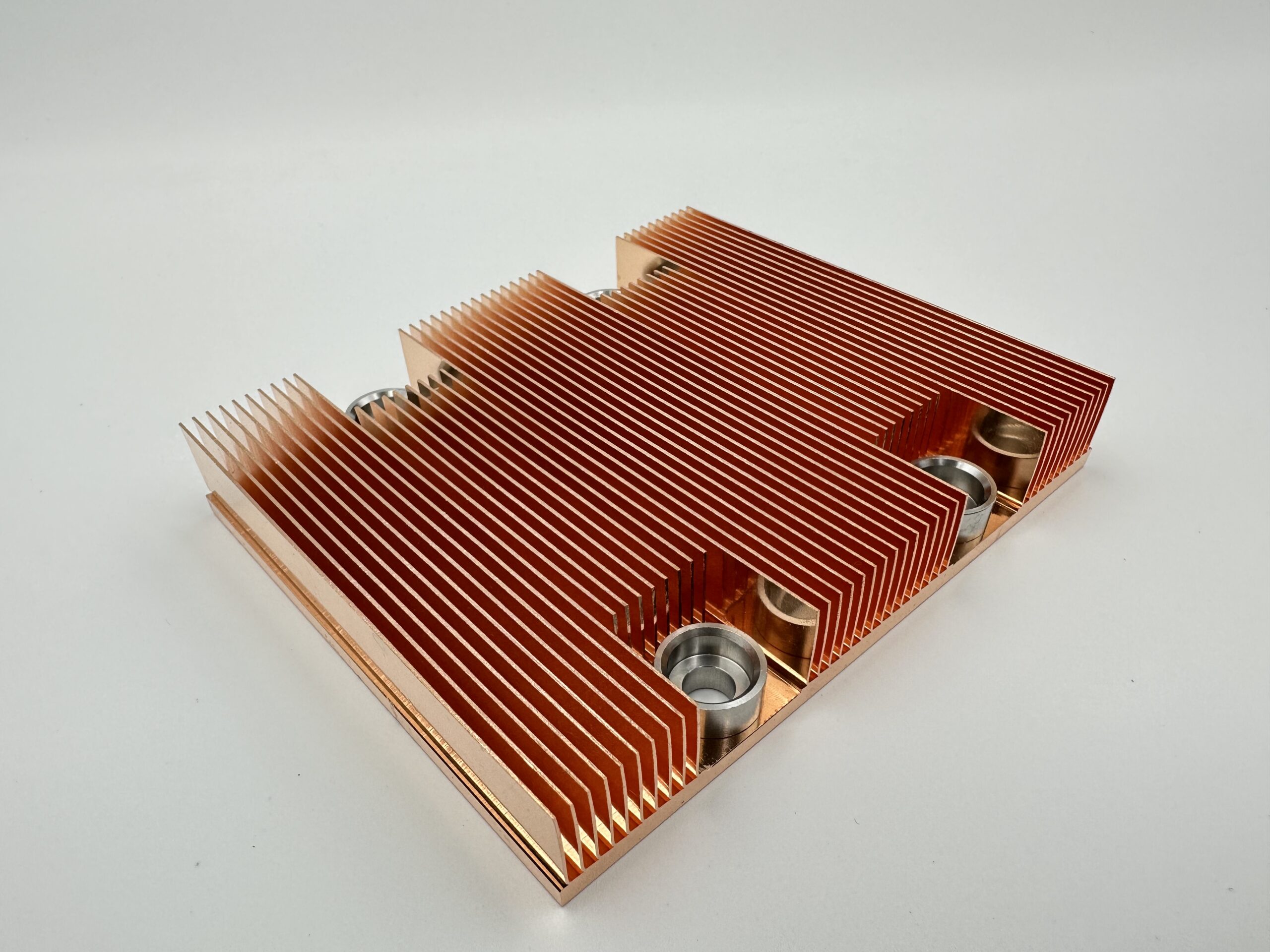

A skived heatsink is a highly efficient thermal management solution known for its superior performance compared to other manufacturing methods. This type of heatsink is crafted from a single block of material, typically copper or aluminum, which eliminates the additional interface resistance found in other heatsink processes like stamped or folded fins that require soldering.

The skiving process produces a heatsink with thin, high aspect ratio fins that are uniformly shaped and densely packed. This design significantly enhances thermal conductivity and ensures optimal cooling performance, especially in high airflow applications. By avoiding the thermal resistance of soldered fins, a skived heatsink provides more effective heat dissipation and improved reliability.

Skived heatsinks are commonly used in demanding environments where efficient cooling is crucial, such as in electronics, LED lighting, and power electronics. Their ability to deliver high thermal performance makes them a preferred choice for applications requiring precision cooling solutions.

Quick Links

Products

Contact Information

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap