Our Solutions

Solutions

At Dingmetal, we understand that quality is the foundation of a company’s survival. Therefore, we are equipped with a range of advanced quality inspection equipment to ensure that every product we produce meets our customers’ high standards. Below are our main quality control devices and their functions:

Forging Solutions

Forging is an excellent solution in specialized fields, capable of forming distinctive and complex shapes, such as arcs and 3D surfaces. In the heat dissipation sector, forged fins can be round, oval, linear, or any combination of these shapes. The manufacturing of cold-forged radiators typically includes secondary processing operations such as holes, chamfers, and steps to minimize material waste.

During the cold forging process, high pressure and low temperature are used to ensure that there are no air bubbles or other impurities in the material. This process not only improves the thermal performance of the radiator but also increases the material’s density. Utilizing 6-series and 1-series aluminum or C1100 copper in forging provides superior performance compared to conventional materials. Additionally, a single set of forging molds can produce radiators of the same design at varying heights. We can also embed copper inserts into the base of aluminum radiators during the forging process to further optimize thermal distribution.

Whether you need customized forged radiators or high-performance heat sinks, Dingmetal offers reliable solutions to enhance thermal performance and overall product quality. We look forward to collaborating with you to advance heat dissipation technology and meet your specific needs.

Die Casting Solutions

Die casting is an efficient metal forming process ideal for producing high-precision and complex-shaped components. At Dingmetal, we specialize in zinc-aluminum alloy die casting, utilizing die casting machines ranging from 280 to 800 tons to meet diverse production needs.

At Dingmetal, we are committed to providing our customers with top-quality die casting solutions. Our advanced equipment ensures efficient production, guaranteeing that each component exhibits excellent surface finish and precise dimensional tolerances. The die casting process not only reduces material waste but also significantly enhances product consistency and reliability.

Our zinc-aluminum alloy die casting products find extensive applications across various industries, including electronics, automotive, and machinery. Whether you require large-scale production or customized solutions, Dingmetal offers cost-effective die casting services tailored to your needs.

No matter what type of die-cast components you require, Dingmetal can provide reliable solutions. We look forward to collaborating with you to drive your project to success.

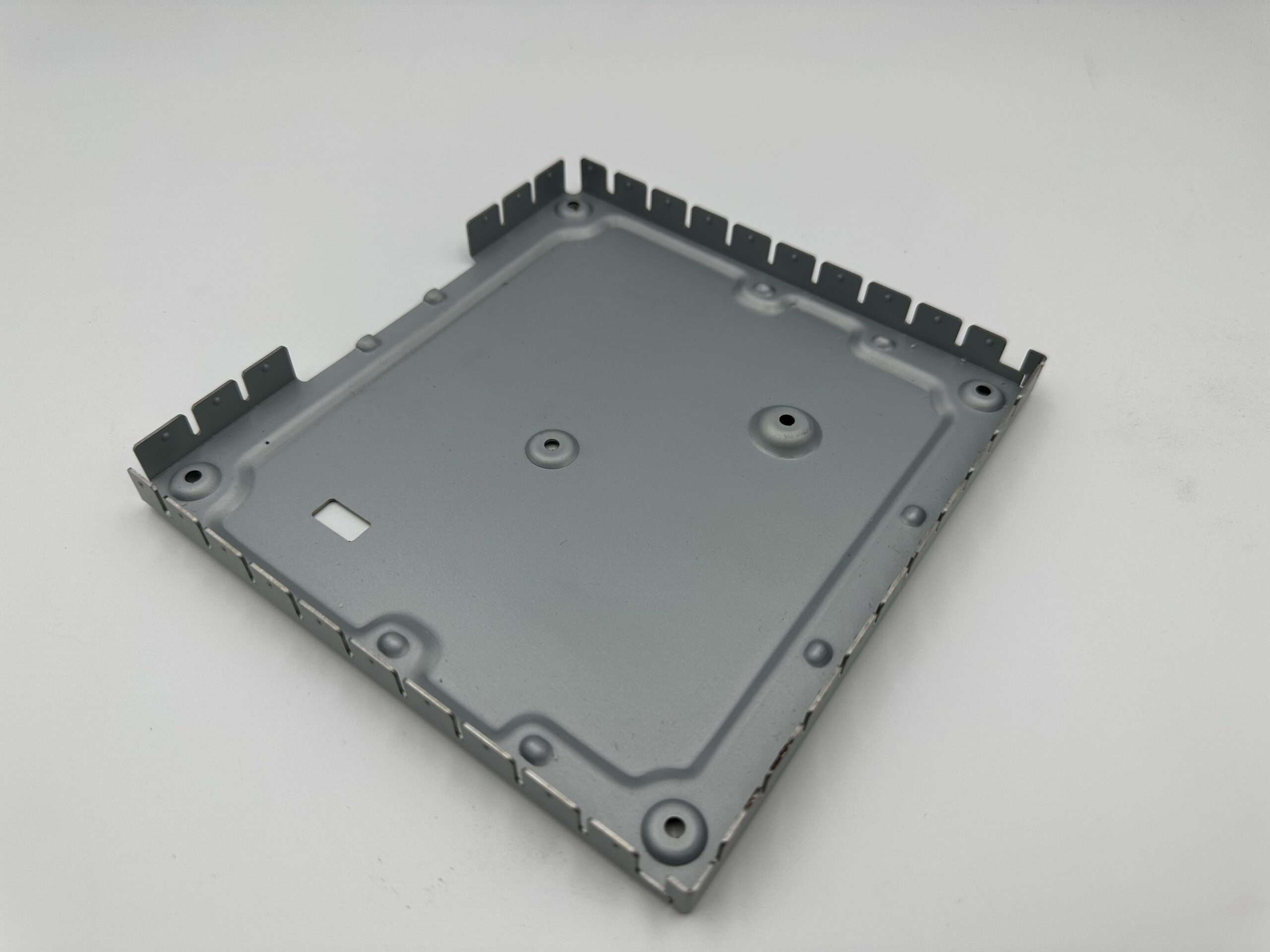

Sheet Metal Solutions

Sheet metal is a crucial manufacturing process widely used across various industries, including electronics, machinery, and automotive. By utilizing advanced equipment such as laser cutting machines, CNC punching machines, bending machines, and hydraulic presses, Dingmetal delivers high-precision and high-quality sheet metal components tailored to meet diverse customer requirements.

At Dingmetal, we are dedicated to providing customized sheet metal solutions. Whether you need complex structural parts or simple enclosures, our cutting-edge technology ensures precision and consistency in every component. Our laser cutting machines allow for efficient cutting, while CNC punching machines handle various shapes and sizes. Additionally, our bending machines and hydraulic presses guarantee perfect shaping of finished products.

No matter what type of sheet metal components you require, Dingmetal offers reliable and cost-effective solutions. We look forward to collaborating with you to drive the success of your projects.

CNC Machining Solutions

At Dingmetal, we are committed to excellence, recognizing that the quality of your products depends not only on advanced equipment but also on the expertise of a skilled technical team. Our CNC machining solutions offer efficient, precise manufacturing services that ensure the success of your project.

Why Choose Our CNC Machining?

FANUC and Mazak CNC Machines: With a solid foundation of FANUC and Mazak CNC machines, we handle both light and heavy-duty machining with ease, adapting to various material and process requirements.

Expert Technical Team: Our technicians boast over 20 years of experience in programming, tuning, and machining. Their exceptional skills and experience guarantee quality that goes beyond expectations, creating a synergy where 1+1 equals more than 2.

Ample Production Capacity: We operate 50 CNC machining centers, including 3-axis, 4-axis, and 5-axis machines. This flexibility allows us to accommodate complex production demands and prototype designs, offering ample capacity for both large-scale production and custom orders.

Comprehensive Quality Control: Using advanced quality control systems such as shadow projectors, CMM, and Keyence laser inspection, we ensure that every component meets high standards with no compromises.

Whether you need custom parts or large production runs, Dingmetal delivers high-quality, tailored CNC machining solutions to drive your project’s success.

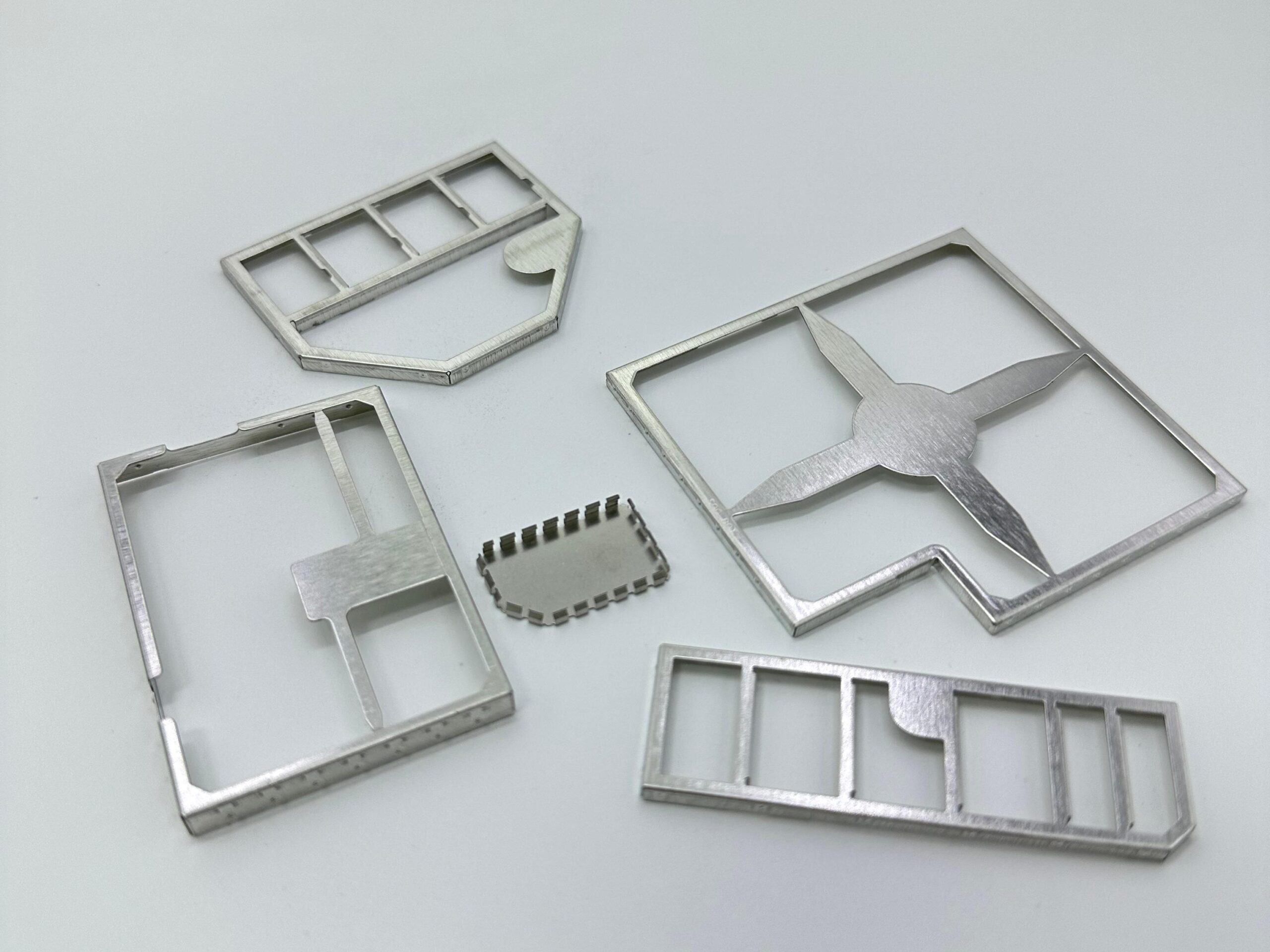

Precision Stamping Solutions

Custom precision stamping is an efficient manufacturing process that transforms metal materials into various shapes and sizes using specialized molds. This technique is particularly suited for industries that require tailored designs and high-precision manufacturing, including electronics, appliances, and automotive sectors. Dingmetal specializes in providing customized precision stamping solutions, precisely catering to the diverse needs of our clients.

At Dingmetal, we are dedicated not only to delivering high-quality products but also to creating significant value for our customers through cost-effective custom services. Our precision stamping capabilities cover parts ranging from 0.5mm to 1500mm in size, accommodating both simple and complex components. We understand that each client has unique project requirements, so we adapt our production processes to ensure that we meet technical specifications while providing cost-efficient solutions.

Our facility features precision presses ranging from 45 tons to 300 tons, allowing us to effectively manage various materials and complexities. Whether you need prototype development, small batch production, or large-scale manufacturing, Dingmetal’s comprehensive production services guarantee efficient and precise delivery. By optimizing production efficiency and controlling costs, we offer customers highly competitive pricing.

With years of industry experience and advanced technology, we prioritize our clients’ interests, helping them gain a competitive edge in the market. By choosing Dingmetal, you not only receive top-quality products but also secure long-term value and reliable technical support

Tooling Manufacturing Solutions

Although our tooling manufacturing services primarily cater to internal needs, we are always eager to assist our clients. If there is a demand for external tooling manufacturing, we will provide professional support and services to ensure your specific requirements are met.

At Dingmetal, we focus on the design and manufacturing of stamping and die-casting tooling for internal production. With over 10 years of experience in tooling design and manufacturing, we can meet various complex requirements and ensure that high-quality tooling is designed, manufactured, and debugged for mass production.

Fastener and Lathe Component Solutions

At Dingmetal, we specialize in providing high-quality, customized fasteners and lathe components, widely used in electronics, machinery, automotive, and other industries. Our product range includes various round turned components, with materials covering copper, aluminum, iron, and various alloys, designed to meet the diverse needs of our customers.

We are committed to offering tailored solutions to our clients. Whether you require simple fasteners or complex lathe components, our technical team will design and manufacture products that meet your specific requirements. With years of industry experience and advanced production equipment, we ensure high precision and excellent quality for each component.

No matter what type of fasteners or lathe components you need, Dingmetal can provide reliable solutions. We look forward to collaborating with you to drive the success of your projects.

Latest News